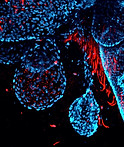

3D BIOPRINTED LUNG MICROTISSUE

Revolutionizing respiratory health through the power of stem cells and 3D bioprinting.

Creating complex tissue by combining 3D bioprinting with the power of self-assembly. We call our lung microtissue: RESIPIRE.

Our newest developments in bioprinting led us to recreate the fundamental units of the complex human lung - the bronchioles, the alveolar airsacs, and the vasculature. We envision our technology to be key in answering unmet needs in various application areas.

Key Areas of Application

BIODEFENSE

Investigate how pathogens interact with lung tissue and enhance protective strategies.

THERAPEUTICS

TESTING

Quickly weed out non-efficacious drug candidates using our high-fidelity human model.

DEVELOPMENTAL

STUDIES

Assess toxicity of drug candidates to prevent complications with the respiratory tract such as fibrosis.

Advantages

RESPIRE™ 3D printed lungs bridge the gap between simpler in vitro respiratory models (organoid and organ-on-chip technologies) and whole animals. It is a full distal lung model containing the bronchial and alveolar epithelia and their associated mesenchymal and vascular cells. Since it's comprised of human cells, RESPIRE™ is expected to perform similarly to the human distal lung. This makes it indispensable in research where animal models fail to mimic human-like responses, such as in viral infections.

Bridging the Organ Shortage with Bioprinted Lungs

The average cost of a lung transplant in the US can range from $900k to $1.2M. Furthermore, the 5-year survival rate after a lung transplant is 50-60%.

This needs to change. Frontier Bio is working towards the creation of lab-grown human lungs that will lead to safer and more affordable transplants.